How to Use the Oxygen Depletion Protocol for Attics and Crawl Spaces

HOUSTON, TX – March 1, 2018 – In 2009, the spray foam industry developed the Appendix X fire test standard for spray foam used in attics and crawl spaces. It was developed through the SPFA Building Envelope Committee and has been universally adopted across the United States. Every spray foam manufacturer has an Appendix X-tested-and-approved spray foam for use in attics and crawl spaces but a few companies believe it’s too much trouble to comply with the Appendix X standard. Instead of promoting their Appendix X-certified spray foam, they tell contractors it’s OK to leave the foam unprotected as long as they adhere to the instructions in their research report, but contractors frequently wonder how the attic is supposed to be constructed in order to conform to the manufacturer’s instructions. The answer is somewhat vague and different for individual spray foam products. Let’s take a look.

First, most closed-cell, medium-density spray foams have passed the well-defined Appendix X fire test without a requirement for additional coatings or coverings where only ignition control is required. Attics, where storage is not permitted, are examples of areas these spray foam products can be used without an intumescent coating. There are also low-density, open-cell spray foams from multiple manufacturers that pass the Appendix X test without coatings or coverings. These foams ignite and burn slowly enough to comply with the code without any special construction in attics and there is no ambiguity about their code compliance.

The nice thing for contractors about true Appendix X-rated foams is they can be sprayed in attic spaces before the ceiling drywall is installed, which is a major time and cost saver and is arguably safer for the installer. Because it’s easier to ventilate the attic space when it’s not enclosed, locating OSHA-required supply and exhaust fans and ducting in the space during construction is far easier, and it’s much easier for VOCs to off-gas so odor complaints are reduced.

When an SPF contractor uses the Oxygen Depletion Protocol with a non Appendix X-certified foam, he assumes responsibility for constructing the attic in a specific way. Unfortunately, the foam manufacturers give limited information about how to do this and the code doesn’t address it. All of the manufacturers’ reports say the attic must have access complying with IRC R807, horizontally placed in the attic floor and opening outward toward the living space. The IRC section R807 gives only the rough opening and clearance above the attic hatch but doesn’t offer specs or standards for an outward opening hatch.

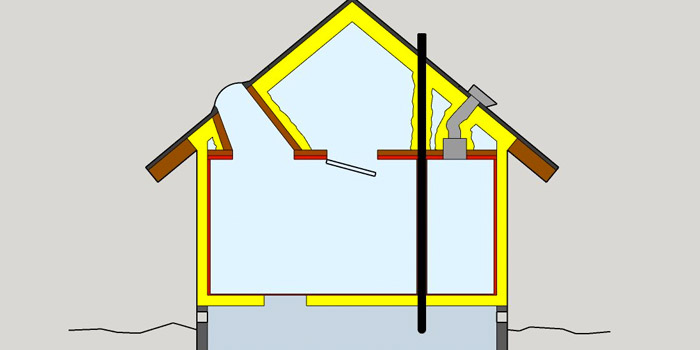

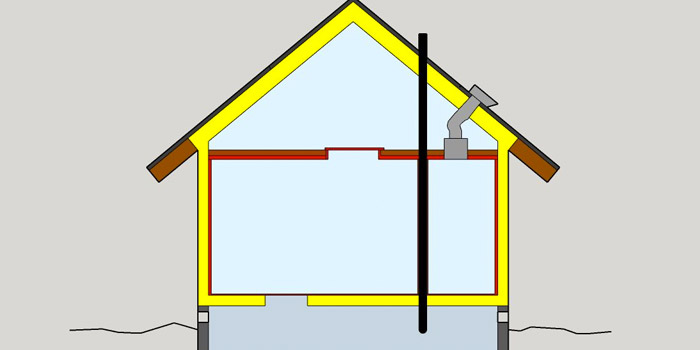

ABOVE: Intertek Code Compliance Research Reports (CCRR) for spray foam claiming the oxygen depletion method for fire control must have skylight wells and vents sealed to the roof deck and the attic floor (ceiling of the house). The drywall must be installed prior to spraying in order to comply with the intent of the CCRR or ICC-ES Evaluation Service Report; BELOW: True Appendix X-rated spray foam can be applied prior to the ceiling drywall, which makes the job safer, faster and much easier to setup and operate the OSHA-required ventilation for worker safety. They can work from ladders and staging from the floor below in most cases. They also save money on the special attic access hatch. The Appendix X standard is peer-reviewed and has been adopted across the country, and every spray foam manufacturer has an Appendix X spray foam system.

The question contractors are asking is: How is the attic hatch supposed to stay closed yet open at the right time? The hatch’s intended purpose appears to be to open in the event of a fire in the attic so that hot gas and smoke can belch out into the living space. So, one would assume that the hatch would be spring-loaded to relieve pressure but not to stay open as the fire develops in the attic.

Spray foam manufacturer’s have told contractors that a pull-down attic stair qualifies as an outward-opening hatch, but building officials frequently equate pull-down stairs with attics as means for storage, which precludes the use of the so-called “Smother Protocol.” One manufacturer offers a metal-framed attic access, which seems like a great idea, but it uses two concealed latches to hold the hatch in place. This begs the question: How can it open if it’s latched? Or, is there a specific pressure required to open the latch? If so, is there any kind of standard to which it’s tested? And since these hatches are not spring-loaded, they remain open once released by some unknown amount of pressure. Doesn’t this allow free flow of oxygen into the attic space? What if the furnace or air handler was running in the attic? They are notoriously leaky and could be creating a negative pressure, which would draw combustion air from the living space through the open hatch to feed the fire.

RELATED Hot Work: Attic Fire Control, How SES Spray Foam Complies With New Assembly Tests

Other manufacturers do not specify the attic hatch design or offer a manufactured solution, rather they point to the Intertek or ICC-ES documents for guidance. Given this limited information, a builder might logically frame the attic hatch from two-by-fours and use door hinges and a window latch to hold it closed. Does this approximate the conditions under which the modeling was done? The drywall guy will no doubt complain mightily! How do you maintain a 15-minute thermal barrier and how is that kind of hatch supposed to be aesthetically finished? Most importantly, how will it open if needed to relieve pressure from the attic?

According to the evaluation or research reports these non Appendix X-compliant foams “must be sprayed on skylight wells or vents, the penetrating item must be covered with a minimum (one to three inches depending on manufacturer)” of SPF. This could be tough. Skylight wells are hard enough when they’re close to the eave, but vents are a real problem. More often than not, the vent ducts used from bath fans to the roof deck are flimsy and poorly attached to the roof sheathing. Blasting them with SPF will be a challenge without dislodging them. If flex duct is used for bath or dryer vents coating them with SPF will void their UL listing. How are chimneys, water heat, and furnace flues handled? There’s a minimum one to three-inch gap between the chimney or flue and combustible materials are required, so you can’t seal the opening around them into the attic or out through the roof. The only alternative would be to frame a chase around each such penetration from the ceiling to the roof deck. Since there’s no accepted industry standard for the thicknesses, the building inspector needs to carefully check each job against the brand of foam used in order to approve compliance.

PVC or ABS pipe is usually used as a drain, waste, or vent pipe, and according to the Intertek and ICC-ES reports, they are required to be sprayed with foam from the ceiling to the roof deck. Electric wires extending from the ceiling to a gable end wall, eave, or roof deck are also required. With any or all of these requirements, there’s no way to spray the unvented attic assembly before the ceiling is installed unless a second trip is made to spray the penetrations and verify proper installation of the attic hatch. How much does that second trip cost and how much longer does it take to spray foam in the closed attic space?

RELATED Hot Work: Attic Fire Control, How SES Spray Foam Complies With New Assembly Tests

The manufacturers using Intertek for their Code Compliance Research Reports all have common language requiring a placard located in the attic visible from all openings:

“NO MODIFICATION MAY BE MADE TO THIS UNVENTED CONDITION. THE ATTIC SHALL NOT BE VENTED. HOLES INTO THE UNVENTED ATTIC SHALL BE IMMEDIATELY REPAIRED AND SEALED. PENETRATIONS OF THE CEILING OR WALL MEMBRANE BETWEEN THE UNVENTED ATTIC AND LIVING SPACE, OTHER THAN THE HORIZONTAL ATTIC HATCH, MUST BE PROTECTED IN AN APPROVED MANNER. THIS UNVENTED ATTIC SHALL NOT BE USED FOR STORAGE. SEE INTERTEK CODE COMPLIANCE RESEARCH REPORT CCRR-XXX ON THE INTERTEK WEBSITE.”

Nowhere on Intertek’s website or any of the spray foam manufacturers’ sites does it say how to “protect in an approved manner” any openings to the attic. Light fixtures penetrate the ceiling, as do bath fans and HVAC boots. How are they to be sealed? There’s no guidance available anywhere on websites or instructions readily available to the builder, remodeler, or homeowner.

The spray foam contractor must take a giant leap of faith to rely on Oxygen Depletion as a fire control method. He’s gambling that the HVAC tech or plumber won’t accidentally start a fire and be unable to escape. It’s just not worth the risk, and considering the details required to comply with the vaguely written reports, it’s very likely to cost far more to spray the job and assure the outward-opening hatch is installed than to use a true Appendix X foam.

The bottom line is this: In most applications, the spray foam manufacturer trains and has clearly written instructions for the spray foam installer. If the SPF contractor sprays off-ratio or mixes water with his Iso, it’s clearly the contractor’s fault and the manufacturer can easily avoid liability. Since the attic hatch and the sealing and coating requirements are so vague and ill-defined, it’s quite likely a judge or jury would heap responsibility back on the manufacturer since they failed to properly inform and train the spray foam contractor and builder. It’ll be an expensive lesson for the industry when it’s finally tested in a court of law. Is it really worth the risk and additional cost?

Contact SES FOAM

Direct any questions about using the Oxygen Depletion Protocol for attics and crawl spaces to SES Foam:

Phone: 855-335-2440 / 713-239-0252

Website: www.sesfoam.com

*Spray Foam Magazine does not take editorial positions on particular issues; individual contributions to the magazine express the opinions of discrete authors unless explicitly labeled or otherwise stated. The inclusion of a particular piece in the magazine does not mean that individual staff members or editors concur with the editorial positions represented therein.