What is the Real Story Concerning SPF and R-value?

JUPITER, FL – March 5, 2018 – I am frequently told by SPF contractors that R-value of the product does not measure SPF’s true energy performance and I don’t need as much R-value of spray foam to get the same results of traditional insulation. What is the true story? Is the SPF community making this stuff up? Can I really get better energy performance with less R-value?

They are not making it up, although some tend to exaggerate the energy performance benefits.

There are three basic test methods identified by the Federal Trade Commission to measure R-value of residential insulation products and included in the ASTM standard specification on SPF C 1029:

ASTM C 177 “Standard Test Method for Steady-State Heat Flux Measurements and Thermal Transmission Properties by Means of the Guarded–Hot-Plate Apparatus;

ASTM C 518 “Standard Test Method for Steady-State Heat Flux Measurements and Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus;”

ASTM C 1363 “Standard Test Method for Thermal Performance of Building Assemblies by Means of a Calibrated Hot Box;” (recently replacing ASTM C 963)

When tested according to FTC and ASTM C 1029 requirements, SPF’s R-value ranges between 5.8 to 6.8 per inch for medium density SPF (1.5 - 2.0 lbs/ft3) and between 3.4 to 4.1 per inch for low density (0.04 - 0.75 lbs/ft3) SPF

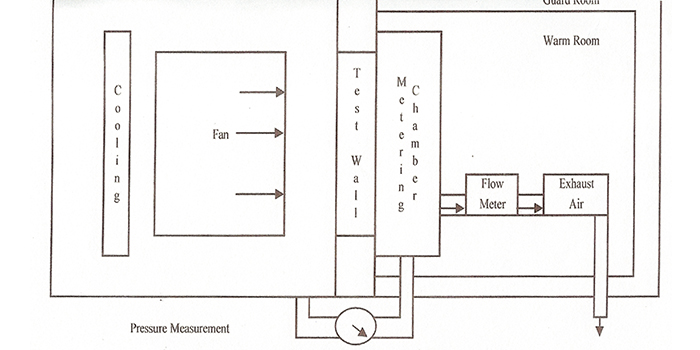

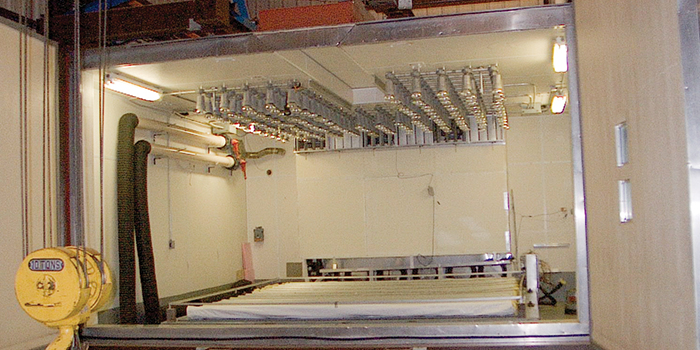

(Above) Guarded Hot Box Diagram; (Below) A Guarded Hot Box can preform ASTM 1363 R-value Measurements

RELATED Hot Work: Attic Fire Control, ASHRAE Publishes 2017 Version Of Thermal Comfort Standard

These test methods are fairly accurate and reproducible, but only measure conduction within a narrow temperature range (median temperature 75 degrees F with a temperature differential of less than 50 degrees F). The tests do not measure convective or radiant heat. They do not take into consideration R-value reductions caused by thermal bridging, humidity, large variations of temperature, air infiltration, and wind.

SPF applications installed properly can air seal the building, reduce convective currents, and reduce thermal bridging and radiant energy heat gain into buildings. When tested in conditions that incorporate air pressure, convection, and high and low temperatures, SPF applications consistently perform 20 percent to 45 percent better than equal R-values of traditional insulation products.

Wall assembly being sprayed for a guarded hot box test in accordance with ASTM C 1363

The claims you have heard are most likely based on these tests and historical evidence of lower energy use with SPF applications. The leakier the building and the more extreme the temperature, the more SPF can help save energy.

Also consider the rule of R-value diminishing returns. As reported in an article by Roger Morrison titled “The Law of Diminishing Returns Its Effect on Insulation Decisions,” depending on the climate and temperature differences between inside and outside environment, additional insulation provides less and less efficiency in retarding heat transfer through an assembly, as well as less economic benefit. As an example, Morrison determined there would be little economic difference between 2.5 inches of closed cell foam in a wall assembly in Lansing, Michigan over 3.5 inches.

Attic assembly being tested in a guarded hot box in accordance with ASTM C 1363

Research conducted at Oakridge National Laboratories by R&D Research and at Architectural Testing Inc by NAHB Research Center and the Spray Polyurethane Foam Alliance. (Test reports available from SPFA at sprayfoam.org)

The Law of Diminishing Returns and Its Effect on Insulation Decisions; Roger Morrison