Raising The Ocean Floats All Boats

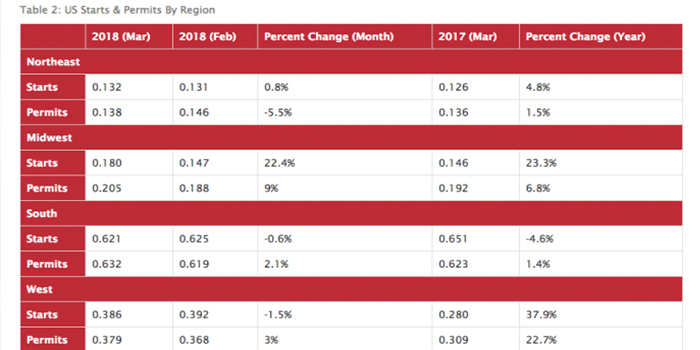

HOUSTON, TX – June, 2018 – The U.S. economy is strong. Housing starts are back to pre-recession levels and certain areas of the country are seeing year-over-year growth in new permits of over 20 percent. Spray foam contractors and systems houses are flourishing and we’re growing our market share due partly to acceleration of the construction industry and partly to our industry promotion of the features and benefits of spray foam.

Including the unvented attic in residential and building codes has been very important for the spray foam industry. We can save money for those paying the energy bills and we improve comfort for occupants, especially in hot climates where vented attics can exceed 150°F. The builder benefits by locating the HVAC duct system inside the conditioned envelope without having to create soffits and a dedicated mechanical room.

Unvented attics were a huge advantage to our industry when we started building them nearly 20 years ago because SPF sticks to the roof deck and seals at the eaves with a single pass of the spray gun. No other insulation type could come close to the increased performance and ease of installation. There was a problem, though. At that time we had a fire performance test that was clearly inappropriate for use in occupied buildings and we were challenged by the International Code Council’s Evaluation Service to fix it or they would fix it for us. In the spirit of working together for the betterment and protection of our entire industry, we fixed it. We spent close to $200,000 and untold hours of our SPFA members’ time to develop and peer-review a robust standard that has stood the test of time. We created, field-tested, and validated the Appendix X fire protection standard for SPF applied in attics where the space is accessed only for service of utilities.

The Appendix X test defined an ignition rate directly comparable to a prescriptive ignition barrier listed in the residential and building codes. The purpose of ignition barriers is to allow SPF in the attic space to be left unprotected by a thermal barrier only if it is slow to ignite and propagate into a fire that might be otherwise inescapable for a workman or homeowner working in the attic. Slower burning foam or a coating to slow ignition of the foam was our goal and is the reason the code allows ignition barriers instead of requiring thermal barriers to protect SPF in attics.

Little did we know at the time we developed this standard, most 2 lb. closed-cell foams (medium density) naturally burn slowly enough to pass this test without a coating or covering. 0.5 lb, open-cell foams (low density) available at the time could pass the Appendix X test only with a coating and intumescent coatings fast became the best and easiest option. It took only a couple of years before multiple Appendix X-compliant half-pound, open-cell foams were introduced. These formulations require no coating or covering and are sprayed the same as other low-density foams but they all require a simple but important processing step. They must be vigorously mixed before and during application.

For hundreds of the best SPF contractors, including many of the very large and savvy spray foam businesses, this is an easy procedure to follow in order to get the immense benefit of safely applying foam without an additional ignition barrier coating or covering. They spray foam knowing they’re in compliance with universally accepted codes and standards. These highly successful contractors would not dream of trying to circumvent code requirements. They have way too much invested in their businesses to risk it all to save a few minutes on a job.

Our industry defines an ignition barrier as a building code permitted protective covering applied over foam plastic insulations, including SPF, in attics and crawlspaces to increase the time it takes for the foam plastic to become involved in a fire. The Appendix X standard defines a test with a pass/fail threshold to qualify code equivalency for a spray foam assembly. The building code requires an ignition barrier, not a means of suppressing a fire that’s already burning. In many industry professionals’ opinions, the oxygen depletion protocol of fire suppression does not meet the intent of the building code as it does not increase the time it takes for the foam plastic to be involved in a fire. Further, they believe the method is legally indefensible.

The fact is there’s no need to stray from industry-approved fire protection standards. It’s faster and cheaper to spray foam that passes Appendix X with or without a coating than it is to make a second trip. Since Appendix X is very clear and easily understood by architects, general contractors, spray foam contractors, homeowners, and code officials, responsible SPF contractors who are risk-averse are unwilling to expose their reputation and the lives of those who might accidentally start a fire in an unvented attic where oxygen depletion is the only fire protection.

Spray foam used in unvented attic assemblies is relatively new compared to polyurethane used in automobiles, furniture, and cushions. Since we first started using foam plastics in our cars, homes, and buildings in the 1940s, we have endeavored to make them slow to ignite and burn. As an industry, we developed the California 117 test for furniture and the MVSS 302 test for automotive cushions. These mandatory test standards have protected American families by allowing only slow-burning foam to be used for cushions and bedding.

Source: SBC Magazine

Until recently, our SPF industry’s focus has been to produce and sell foam plastics that are slow to ignite and slow to burn. Foams using the so-called oxygen depletion protocol can pass their test more easily when the spray foam burns rapidly so the oxygen in the unvented attic is quickly depleted. This is contrary to everything the polyurethane industry has strived for over the past 70 years. This protocol is not good for our industry. It does not promote fire safety. It is arguably not code-compliant since it does not attempt to slow ignition to allow a worker in the attic to escape. Using the oxygen depletion protocol to circumvent code-required ignition barriers potentially exposes the spray foam contractor to product safety liability. SPF manufacturers who offer and promote unprotected foam but fail to adequately inform and train contractors will likely share this liability. Listing agencies might also be implicated when someone dies in an attic using the oxygen depletion protocol. Listing agencies have a responsibility to thoroughly examine both the testing protocol and the operations and application guides for a product they list. With the lack of detailed written guidance and instruction for this protocol, it seems hard for them to defend their listing as safe and in our industry’s best interest. Yes, they are paid handsomely for testing to the oxygen depletion protocol as is the fire science consulting company advocating this method, but our industry doesn’t need it and it can bring immeasurable harm to all of us should someone lose his or her life in one of these spaces where unprotected foam is left exposed.

We have two industry-funded and professionally operated trade organizations for the spray foam industry. The Spray Polyurethane Alliance (SPFA) is a contractor-focused association with a robust outreach program and is committed to marketing spray foam. The Spray Foam Coalition (SFC) is formed within the Center for Polyurethane Industries (CPI), and American Chemistry Council (ACC). Both organizations spend industry dollars to generically promote spray foam to architects, builders, general contractors, building officials and the general public. The idea is to raise the SPF ocean to float all boats. Our spray foam contractor boats float higher when the market is growing and we’re not distracted by controversy, accusations, and innuendo. Our SPF systems houses’ boats float higher as do their basic materials suppliers like those who make catalyst, surfactant, flame retardant, blowing agent, polyols, and all of the other essential ingredients. If we have a major problem in our industry, we could drain our collective ocean.

It’s simply not worth it. Straying from industry standards cannot be good for any of us long term. There are plenty of spray foam products available in the industry, which require no coatings and no second trip. The spray foam contractor can spray the roof deck through the ceiling joists and get the job done without having to spray an ignition barrier coating. Every spray foam manufacturer also offers a formulation that requires a coating but most can be installed about an hour after the foam is sprayed, so again, a second trip is not required.

We have the technology. We have the knowledge. We have an easily understood and peer-reviewed industry standard for fire protection in attics and crawl spaces; Appendix X. It’s time for our industry to stop taking shortcuts for short-term gain and get back to building a sustainable spray foam market based on 70 years of polyurethane experience. With the oxygen depletion protocol, we are providing those who would limit our growth with the ammunition they need to slow the acceptance of foam and the erosion of their market share. To take the stance that “foam is not that combustible, and hard to start on fire” is bizarre and we must stop. We must abandon the so-called oxygen depletion protocol so we can grow and prosper together.

Contact SES FOAM

Direct any questions about Appendix X and the spray foam industry to SES Foam:

Phone: 855-335-2440 / 713-239-0252

Website: www.sesfoam.com

*Spray Foam Magazine does not take editorial positions on particular issues; individual contributions to the magazine express the opinions of discrete authors unless explicitly labeled or otherwise stated. The inclusion of a particular piece in the magazine does not mean that individual staff members or editors concur with the editorial positions represented therein.