My Pressures Aren’t Balanced, What’s the Problem?

SPRAY FOAM MAGAZINE – We see quite a few posts on various social media sites where questions arise related to non-balanced or non-equal spray pressures, the infamous “E24” error code, and what could be the problem. They have supposedly tried everything—cleaned the y-strainer, changed the spray gun, new mix chamber, etc. and still have the issue. Better yet, a picture is posted with the request of “HELP???”

Sorry, but I haven’t a frigging clue!!! Why, one would ask? Well, only a static picture is posted with no additional information provided, or only limited information. And then the questions and responses go back and forth, which takes more time. One needs to provide a video of the dynamic pressures working to properly troubleshoot this issue.

Much of this could actually be easily resolved if one had proper training on the equipment use and processing. Even reading or referring to the equipment operational manual would help. But alas, that is unfortunately usually the last resort. It is easier to post a question on social media and wait for the various answers, some of which are actually misleading at times.

Pump Basics

Your proportioning pumps do NOT make pressure, they provide flow of material, and the pressure comes from how that material flow is normally restricted, i.e. spray gun orifices. Your static pressure (pressure at rest) will typically be higher than your dynamic pressure (spray pressure). This is normal and can be observed on the gauges. When you increase the static pressure, you are actually increasing the speed of the pump, resulting in a higher material flow rate. This then shows as a higher pressure due to the restriction in the spray gun at that higher flow rate.

For a practical example, take a polyurea spray application where the static pressure is set to 2500 psi. When using a spray gun with a “29” chamber, one will note a dynamic spray pressure of about 2100 psi. But change that chamber to a “42” in size, and the dynamic spray pressure will drop to about 1800 psi, with no adjustments to the proportioning unit. Why? Well the “42” is larger in size, thus less restriction and easy to flow, lower pressure.

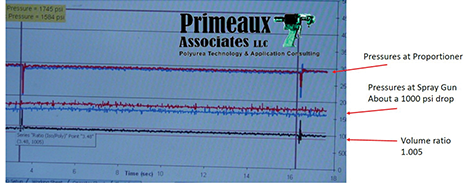

FIGURE 2 is from an OEM continuous application of a polyurea based coating system. While the pressures are different between the

ISO component and the resin blend (of about 250 psi), the application was still on the proper volume ratio, noted as 1.005.

This picture also shows the realized pressure drop from that noted on the proportioning unit, to actually what is seen at the spray gun, where the polyurea coating is being produced. This of course was due to hose length used, hose internal diameter, and multiple installed 90° elbows in the hose line. And yes, for most polyurea spray systems, the ISO pressure is typically higher than the resin pressure, due to higher viscosity of the ISO side. While this has been discussed in a previous article, good material was still being produced.

Cavitation / Starvation and Restriction

The two most common issues with spray processing and “pressure” here are Cavitation / Starvation and Restriction. When one experiences these issues, it is important where to start for troubleshooting and addressing the issue. Also for diagnosing these issues, this needs to be done while spraying (Dynamic pressure) and not at rest or static pressure.

So Cavitation / Starvation is where there is insufficient flow of one, or both materials to the proportioning pump. This is characterized by one gauge dipping down during spraying while the other gauge remains a normal Dynamic pressure. If you stop spraying and check the gauges (Static pressure), one gauge will show normal, while the other shows higher pressure, thus giving a false indication that there is a restriction from the gun back.

To troubleshoot this, one starts at the source of material supply and works to the proportioning pump. Common causes can be:

- material supply pump not on / working, not large enough pump

- material supply viscosity to high, cold material

- introduced air in supply line

- from a drum change-over, or running dry

- partially plugged ISO supply hose

- pump foot valve stuck, not seating properly or came unscrewed

- supply valves closed, yes this happens often

- y-strainer screen plugged

- proportioning pump seals bad, check-ball not seating properly

- incorrect gun setup

Incorrect gun setup can lead to cavitation, due to the setup designed for higher output than the proportioning system can deliver. This would typically show cavitation on both gauges.

Restriction can be either partial or complete restriction in the system. This will be noted by one gauge showing the proper or normal spray Dynamic pressure and the other showing a much higher pressure. Causes include:

- plug in spray gun / hose

- plugged / incorrect gun screens

- low primary / hose heat: higher viscosity, harder to pump

- manual valves not open at

- spray gun

Here is a scenario that happens more often than not. One starts off spraying and notices a higher pressure on one side than the other. If after spraying for a while, your spray pressures are slightly lower or more equal, and no machine adjustments have been made, that is an indication that the material has become warmer (up to heat), thus lowering the viscosity of the material and reducing the restriction, lower pressure. Higher viscosity liquid - harder to pump (higher pressure) / lower viscosity liquid - easier to pump (lower pressure).

A basic rule of thumb here, for Cavitation / Starvation, start at the material supply and work to proportioner; for Restriction, start at the gun and work back to the proportioner. Let’s also keep in mind, one could have faulty gauges on the proportioner.

Flow Meters

Traditionally through experience, we have monitored the spray pressures, along with other visual indications that support the fact that one is processing at the proper ratio and system mix. Flow meters can and are used on plural component systems to monitor equal, or proper, volume flow rate of each component. Some of these may actually be installed on independent drive systems such that flow adjustments can be made “on the fly” while processing, so to speak. Many will state: “Use of flow meters on our equipment will insure proper volume ratio, resulting in quality foams and/or coatings produced!”

While part of that statement may be true, the other half is FALSE! Why? Having flow meters will show and document that one is at the proper volume ratio to the gun.

If you are not getting good and proper mix in the spray gun, one will not be making good foam and/or coating. Flow meter use gives no indication of proper and complete mix in the spray gun setup.

Also, as with polyurea systems, if one does not properly agitate the resin side, pigment will have settled to the bottom of the drum. One might be pumping the proper “volume ratio” as shown via the flow meters, but will be “off ratio” system INDEX-wise due to pumping mostly pigment and not the proper reactive resin blend. This can also happen with some spray foam system resin blends.

Bottom line, the use of flow meters can provide a false sense of security that quality foam and/or coating has been produced. Visually monitoring the spray pattern can help here. If one is getting distorted spray patterns, fingers in the pattern, or heavy spots, pattern pulsing, etc., that is typically an indication of incomplete mix of the plural components. Stay tuned, there is a common mechanical device that can be employed to do this and will be the subject of a detailed technical paper coming soon.

It’s all about being educated, observant, and prepared in your application work. Remember the first article back in early 2023 – be sure to follow the 3 C’s for success.

About the Author: Dudley J. Primeaux II is the owner of Primeaux Associates, LLC, a polyurea technology and application consulting company. He has been directly involved in the polyurea story since the early development in the 1980s. His background is in Organic Chemistry, where he holds a Master of Science Degree. He also has a very high degree of mechanical abilities, which proves useful in field application / equipment usage.

Dudley has authored over 40 technical papers relating to the polyurea industry, is named inventor on over 25 U.S. Patents and eight European Patents. He has experience in the preparation of new raw materials, formulation development, application equipment usage, field application work, and failure analysis of coating / lining projects. He knows more about “polyurea” than most in the industry.

Direct any questions about polyurea to dudley@primeauxassociates.com

For use by SprayFoamMagazine.com & Spray Foam Magazine