Innovation in Insulation

SPRAY FOAM MAGAZINE – Spray foam insulation is a crucial component in modern construction, offering superior insulating properties compared to traditional insulating materials. However, the environmental impact of the use of hydrofluorocarbons (HFCs) as blowing agents raised significant concerns and created a focus on transitioning from HFC-based blowing agents to those with low global warming potential (GWP). HFC foams have been phased out in Canada since 2021, and HFC foams cannot legally be manufactured in the United States on or after January 1, 2025.1 In this article, we explore HFC issues, alternatives and their advantages, and find that the spray foam industry is far ahead of the deadline to phase out HFCs by the end of 2024.

The primary issue with HFCs is their high GWP, which measures a substance’s ability to trap heat in the atmosphere compared to carbon dioxide. HFCs can trap thousands of times more heat per unit than CO2, contributing significantly to global warming.2 Even though HFCs are present in the atmosphere in smaller quantities than CO2, their potent warming effect makes their reduction a critical goal in combating climate change. Closed cell spray foam with an HFC blowing agent has a GWP of 1000 whereas closed cell spray foam with a low GWP hydrofluoroolefin (HFO) blowing agent is 1, which is equal to water! (See Enverge product data.)

The shift to low GWP blowing agents in spray foam insulation is an environmental imperative and aligns with national and global regulatory trends. On December 27, 2020, the American Innovation and Manufacturing (AIM) Act of 2020 was enacted, authorizing the Environmental Protection Agency (EPA) to address HFCs by providing new authorities in three main areas: to phase down production and consumption of HFCs to 15% of their historic baseline levels by 2036, manage HFCs and their substitutes, and facilitate the transition to next-generation technologies through sector-based restrictions.2

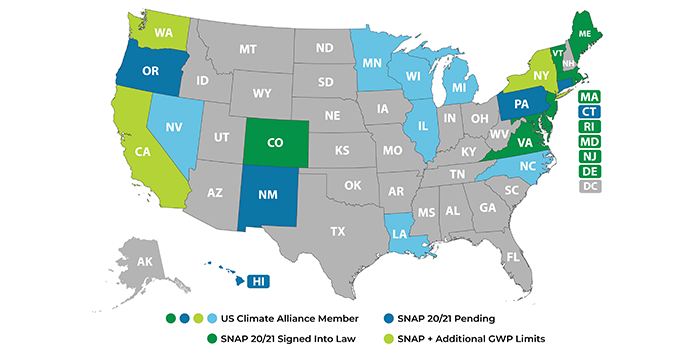

Several states have already taken steps to impose restrictions on HFCs in products by joining the US Climate Alliance, and many of those have enacted varying levels of SNAP, the EPA’s Significant New Alternatives Policy program established under the Clean Air Act.3

The Kigali Amendment to the Montreal Protocol, which aims to phase down the production and use of HFCs by more than 80% over the next 30 years,4 reflects an international commitment to reducing greenhouse gas emissions. By transitioning to low GWP alternatives, manufacturers and users of spray foam insulation are complying with these evolving regulations.

The Spray Foam Transition

In anticipation of the move away from HFCs, many spray foam manufacturers began working on hydrofluoroolefin (HFO) and low GWP spray foams over a decade ago. While the transition to low GWP blowing agents was an obvious environmental benefit, it was not without challenges.

Those challenges included:

Performance and Compatibility: New blowing agents needed to meet or exceed the performance standards set by their HFC counterparts. They also needed to be compatible with existing spray foam equipment and formulations.

Cost Implications: Developing and deploying new technology often comes at a higher initial cost. This factor can be a barrier for manufacturers and consumers, although long-term savings, tax credits, and regulatory incentives can offset these costs.

Industry Adaptation: The entire value chain, from chemical manufacturers to end-users, needed to adapt to this change. This adaptation required education, training, and sometimes, equipment upgrades.

These challenges were overcome, and most manufacturers now offer non-HFC, Low GWP closed cell spray foam for the market, and the push to phase out HFC has led to some unexpected and interesting improvements in spray foam insulation.

Advantages of Low GWP Blowing Agents

Reduced Environmental Impact: The most apparent benefit of low GWP blowing agents is the reduced contribution to global warming. This change is crucial in the broader context of sustainable development and climate change mitigation.

Increased Energy Efficiency: Interestingly, some low GWP blowing agents have shown to improve the thermal performance of spray foam insulation.5 R-Values of low GWP foams show an increase of 10% over HFC foams.6 This enhancement means buildings require less energy for heating and cooling, further reducing its carbon footprint.

Overall Foam Performance: The shift towards HFO spray foams brings performance enhancements over HFC spray foams. HFO spray foams offer improved yield and coverage, easier application, consistent quality, and higher R-values, resulting in the need for less product during installation, which can lower or match the cost of older systems while providing more insulation per application.7

Market Adaptation and Innovation: Transitioning to new technologies often drives innovation. The development of low GWP blowing agents has stimulated research into more sustainable and efficient insulation solutions for continued environmental benefits.

Regulatory Compliance and Market Access: As global regulations tighten around HFCs, transitioning to low GWP alternatives ensures compliance and continued access to markets that may restrict high-GWP products.

Achieving a total phase-out of hydrofluorocarbons in closed-cell spray foam by the end of 2024 is a certainty. The move to low GWP blowing agents aligns with global environmental goals, regulatory trends, and market demands for greener building materials. While challenges existed early on with this transition, the combined efforts of industry stakeholders, governmental agencies, and consumers overcame these hurdles, leading to a more sustainable future for our industry and our planet.

*This page is meant to serve as an educational tool and is not intended to provide compliance advice. We encourage you to work with a compliance expert on your specific regulatory strategies.

Contact Enverge If you have any questions about any of Enverge’s spray foam products or services:

713-239-0252 // EnvergeSprayFoam.com

*Spray Foam Magazine does not take editorial positions on particular issues; individual contributions to the magazine express the opinions of discrete authors unless explicitly labeled or otherwise stated. The inclusion of a particular piece in the magazine does not mean that individual staff members or editors concur with the editorial positions represented therein.

For use by SprayFoamMagazine.com & Spray Foam Magazine