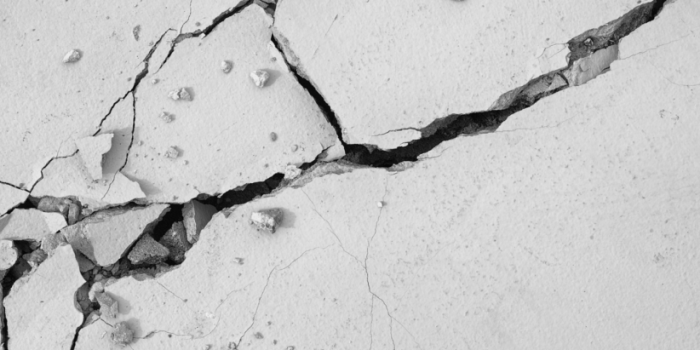

Sealing Gaps and Cracks

Building construction involves many transitions between materials and systems. At each of these transitions, gaps are provided to allow for movements between materials. One component foam sealant, also known as foam sealant or foam-in-a-can, can be an ideal product for sealing gaps and cracks around windows, doors, and other penetrations.

One component foam sealant bonds readily to wood, masonry, metal, glass and many plastics. It sets and cures quickly, hardening into a protective shield that helps prevent air from crossing the foam barrier where it is installed.

Typical applications for single component foam sealant include:

- Filling gaps and cracks around window and doorframes

- Closing gaps around outside-wall penetrations made by gas lines, water pipes or dryer-vent hoses

- Filling gaps inside the home caused by electrical line or HVAC vent penetrations

Common Applications

- Windows and Doorframes: Filling gaps and cracks around window and doorframes to improve insulation and prevent drafts.

- Wall Penetrations: Sealing gaps around exterior wall penetrations caused by gas lines, water pipes, or dryer vents.

- Interior Penetrations: Closing gaps inside the home created by electrical line or HVAC vent penetrations, helping to maintain energy efficiency.

Enhanced Energy Efficiency

Moisture and Pest Resistance

Specialized Applications

- Fire-Rated Foam Sealants: Designed to seal gaps while maintaining fire resistance, these are ideal for use in areas where fire codes apply.

- Acoustic Sealants: Providing both insulation and soundproofing, these are useful in multi-unit buildings or homes requiring noise reduction.

- Flexible Foam Sealants: Suitable for areas subject to frequent movement or vibration, such as around machinery or HVAC systems.

Application Tips for Best Results

To maximize the performance of one component foam sealant:

- Prepare the Surface: Ensure the surface is clean, dry, and free from debris for optimal adhesion.

- Apply Evenly: Use a foam applicator gun for precision and control, especially for tight spaces or detailed work.

- Allow Proper Curing Time: Follow the manufacturer’s guidelines for curing to ensure the foam sets properly and achieves its full strength.

- Trim Excess Foam: After curing, any excess foam can be trimmed and sanded to create a clean, professional finish.